3D cameras can perform tasks such as object positioning, size measurement, and quality inspection, etc., and their applications in industries, logistics, and other scenes are increasing rapidly. However, ambient light interference often occurs in actual deployment, affecting accuracy and stability of 3D cameras, and besides, shading facilities required are often expensive.

After long-term painstaking research and development, Mech-Mind launched a new generation of Mech-Eye Laser industrial 3D camera. Based on self-developed structured light technology of high-speed laser, this series of cameras are excellent in resistance to ambient light,and can image many objects with high quality under the interference of sunlight >10000 lx (the ability of resistance to ambient light interference is related to the material of object). Mech-Eye Laser has been used in batches for many practical scenes such as depalletizing & palletizing, machine tending, high-precision assembly/positioning, and gluing, etc.

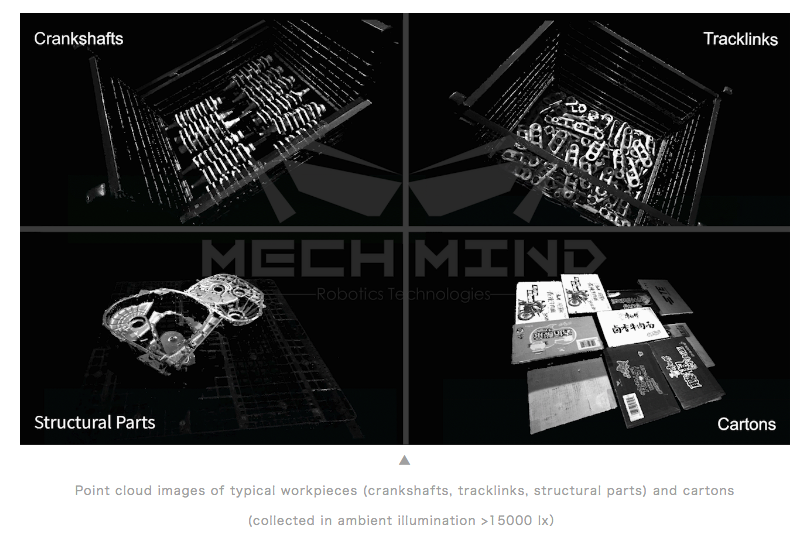

Under the typical ambient illuminance (>15000 lx) of the actual plant , Mech-Eye Laser can generate high-quality 3D data with more complete structure, richer details, and clearer boundaries for various types of typical workpieces (including stacked workpieces, complex and precise structural parts, etc.), cartons, sacks, etc. compared to other 3D cameras. They are very suitable for various scenes that are easily interfered by ambient light in such fields as manufacturing workshops, logistics warehouses, construction, and steel, etc., with stability improved and demand for shading facilities significantly reduced.

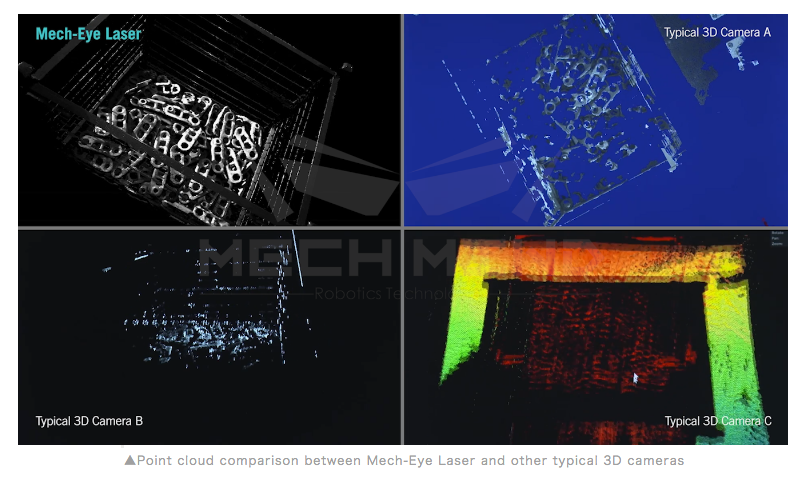

In the experimental environment, we tested and compared ambient light resistance performance of various 3D cameras (including C*, P* and other foreign brand products) in light conditions of different levels. Parameters of each camera have been carefully adjusted to achieve the best results.

In typical lighting conditions (>15000 lx) of the actual plant building, the point cloud data generated by Mech-Eye Laser is obviously more complete and detailed compared with other 3D cameras, as shown in the figure below.

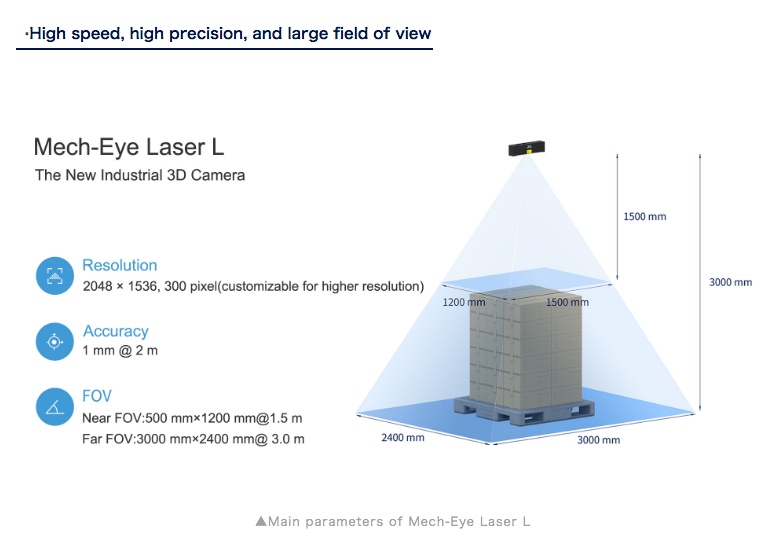

·High speed, high precision, and large field of view

Using self-developed structured light technology of high-speed laser, the scanning time of Mech-Eye Laser can be less than 0.9 s (depending on the material of workpiece and the actual environment). It has advantages of large field of view, high precision, high resolution, and customizable nature (sub-model Mech-Eye Laser L has a resolution of 2048×1536, 3 million pixels, and can be customized to upgrade to a higher resolution). It can meet actual requirements of various typical applications, including large-view depalletizing & palletizing, loading and unloading of workpieces of various sizes, high-precision assembly/positioning, and gluing.

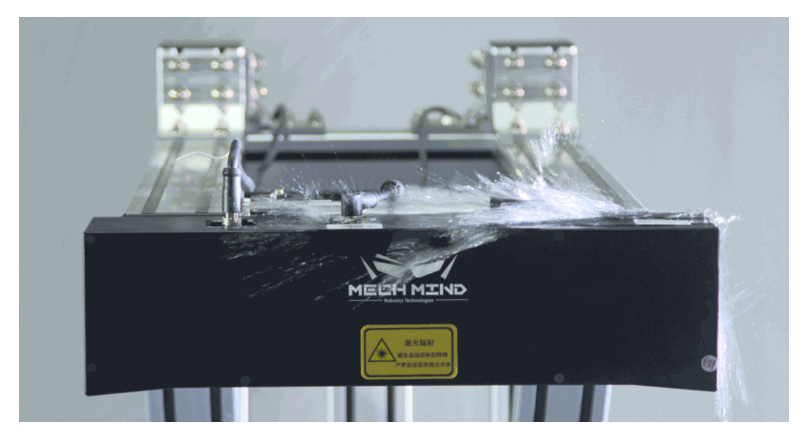

·With industrial-strength design, capable to better meet challenges in actual industrial field

Mech-Eye Laser uses aviation aluminum alloy as shell material, adopts a fully enclosed design, and has a protection class IP65. It has obtained CE, FCC, VCCI and ROHS certifications, and can better deal with harsh environments such as humidity (including water leakage), dust, vibration, and electromagnetic interference that may exist in industrial field.

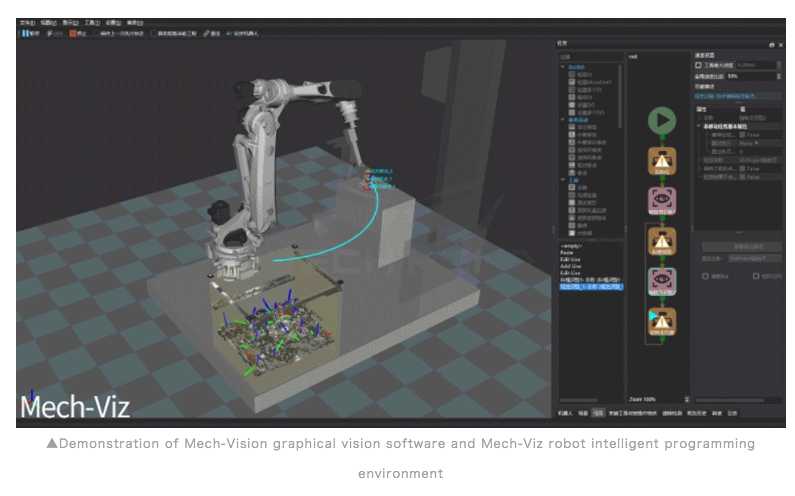

·Open and easy-to-use

Adhering to the philosophy of Mech-Mind’s empowering partners and providing integrators and partners with full-featured, powerful and easy-to-use products, we provide users of Mech-Eye Laser with multi-language and multi-platform SDKs. Users can either choose to develop their own software, or choose to work with Mech-Vision graphical vision software and Mech-Viz robot intelligent programming environment for easy deployment of various intelligent robot applications.

·High cost performance

The price of Mech-Eye Laser is more competitive. In addition to cost savings of the camera itself, human and material investment in customized design/processing, etc. required for shading facilities can also be reduced, thus leading to a higher cost performance.

Background

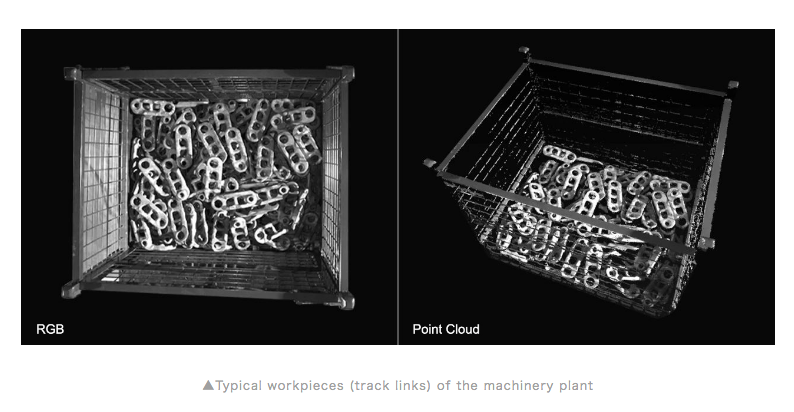

A machinery plant plans to undertake an automation transformation of intelligent robots to some workpiece loading stations. The stations to be transformed are close to the large glass French windows, and ambient light interference is very strong (the average intensity of ambient light is above 10000 lx).

Before using Mech-Eye Laser

The plant uses 3D cameras + large-scale shading facilities to deal with ambient light interference. Due to frequent changes in angle, intensity, and irradiation area of ambient light, the plant needs to design multi-faceted shading facilities to maintain the stability of intelligent robots, which is a complicated design with long cycle, large investment and high risk. In case of a workstation that requires human-machine cooperation, design of an automatic rolling door is also necessary, and financial investment is usually above tens of thousands RMB.

After using Mech-Eye Laser

Even in strong ambient light, Mech-Eye Laser can also generate high-quality 3D data for various structural parts (such as track links) of the plant, thus shading facilities required for these stations are significantly reduced, the cost is cut down and stability is improved.

Mech-Eye Laser is now available on line. If you have any inquires or want to know more details about Mech-Eye Laser, please click ‘Contact Us’ and leave your detail information, or contact your corresponding salespersons, we will do our best to serve for you.

出典:

https://en.mech-mind.net/news_view.aspx?TypeId=5&Id=554&Fid=t2:5:2