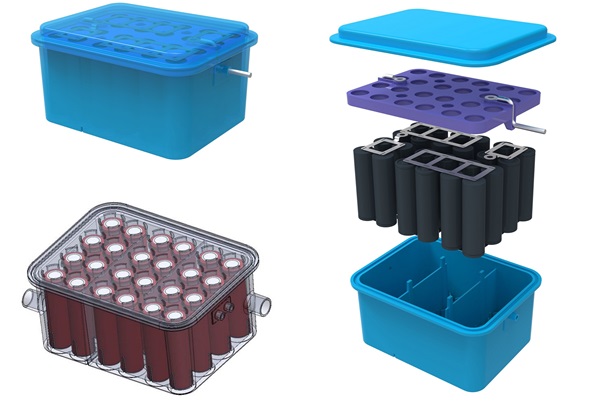

Batteries used in electric vehicles must be actively cooled to function properly and retain their life span. This process, known as fluid cooling, requires airtight seals to keep fluids contained and avoid spills. While several joining methods can be used to weld plastic battery packaging components, those that do not require external agents are less complex and more cost-efficient.

Of these techniques, manufacturers often turn to laser welding as it allows for larger parts, does not require a pre-treatment and offers high-precision, repeatability and control. Covestro LLC worked with Leister Technologies LLC to develop process and material solutions for laser welding fluid-cooled battery modules used in electric vehicles such as new passenger vehicles, electric buses, trucks and other utility vehicles.

この情報へのアクセスはメンバーに限定されています。ログインしてください。メンバー登録は下記リンクをクリックしてください。