Introduction

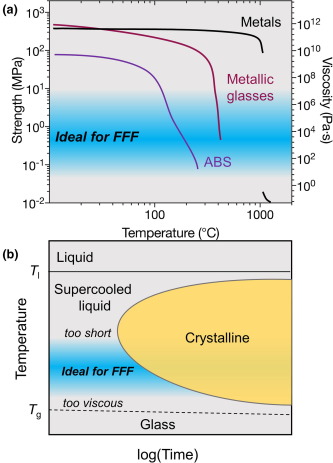

The materials toolbox has traditionally demanded hard choices [1]. While the structural performance of metals is superior to that of thermoplastics, processing of metals is generally challenging (Fig. 1). In contrast, plastics, particularly thermoplastics, can be readily processed into complex geometries, but exhibit inferior structural performance [1]. The high processability of thermoplastics originates from their continuous softening with temperature into a readily formable state.

Figure 1. (a) Property-processability trade-off. Comparisons between material classes by their properties (strength) and their suitability for extrusion based 3D printing (such as FFF). Temperature dependent strength represents the flow stress of the material which can also be translated into a viscosity through , with = as a representative strain rate. The strain rate is estimated from feedstock diameter, nozzle diameter, nozzle length, and printing speed. BMGs can be processed in the ideal processing region for FFF within a viscosity range of 102–105 Pa·s, similar to typical thermoplastics like ABS (Acrylonitrile butadiene styrene). Conventional metals, on the other hand, are either by orders of magnitude too soft (in their liquid phase, bottom part of graph) or too hard (in their crystalline phase, top part of graph) for FFF processing. (b) Time-Temperature-Transformation (TTT) diagram revealing the temperature dependent time to reach crystallization. The TTT originates from the metastable nature of the supercooled liquid, which defines the available processing window for BMGs. TPF-based processing of BMGs requires a protocol balance to yield ideal behavior. This is realized through the processing temperature optimized for low viscosity yet sufficient processing time that can be experimentally realized.

この情報へのアクセスはメンバーに限定されています。ログインしてください。メンバー登録は下記リンクをクリックしてください。