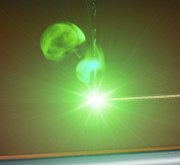

- Vitesco Technologies uses state-of-the-art green lasers from TRUMPF for energy-saving welding of copper

- Due to electrification in the drive, copper welding is currently a key manufacturing process

- Green laser systems are energy-efficient and also reduce manufacturing effort

- Copper welding with green lasers is already being used in a current electronics series project for the BMW group

Regensburg, July 4, 2022. Vitesco Technologies, a leading international manufacturer of modern drive technologies and electrification solutions, is using innovative laser systems from its long-standing production engineering partner TRUMPF. With the introduction of the new green laser equipment for copper welded joints, Vitesco Technologies is among the pioneers in the serial use of this new solution. Compared with infrared laser systems – the standard in copper welding to date – the use of green lasers can reduce energy consumption by up to 20 percent, depending on the application, and thus the CO2 footprint per laser welded joint. At the same time, production becomes more sustainable by the fact that green laser systems cause virtually no copper spatter during welding, which otherwise means more effort during production.

この情報へのアクセスはメンバーに限定されています。ログインしてください。メンバー登録は下記リンクをクリックしてください。