Last fall, we published a blog titled “Micromachining Lasers for Anti-Counterfeiting,” where we explored how laser micromachining can be used to embed microscopic two-dimensional identification codes directly onto the item of interest. In addition to discussing the fundamentals of micromachining in that blog, we highlighted the MicroMake system from Bright Solutions, including how its short pulse width and high pulse repetition rate facilitate ablation to produce ultra-high-resolution machining features. Unlike all of the other laser products sold here at RPMC Lasers, the MicoMake is unique for being a complete turnkey OEM solution for micromachining. As a result, we have decided to dedicate this blog post to take a deeper dive into the MicroMake system itself. In this blog post, we will explain how it differs from all of the other laser systems for micromachining that we offer here at RPMC. This makes it the ideal solution for a wide range of applications, including micro-corrections, track interruptions, and thin film removal.

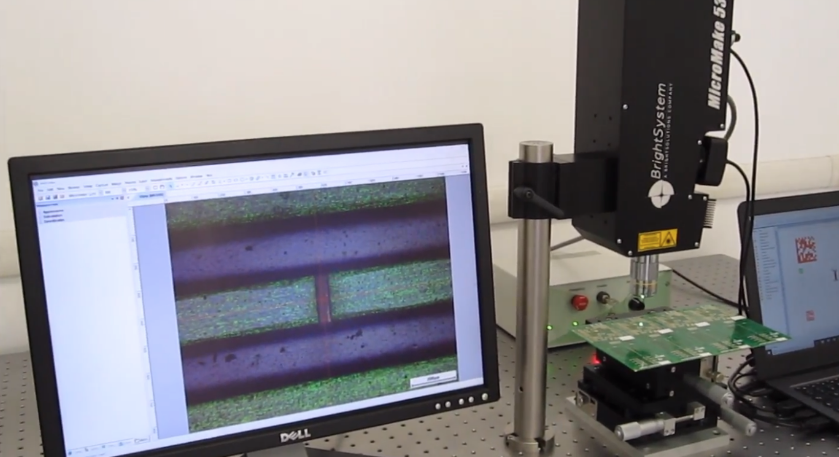

The MicroMake from Bright System is a completely integrated system; containing a compact micromachining laser, a high-quality video microscope, and control software all in one unit. Due to its monolithic system design, it can be easily set up and configured by technicians and operators, without the need for an on-site electro-mechanical engineer. The MicroMake’s user-friendly and intuitive graphical user interface control software allows for the design of any arbitrary shape to be applied as a cutting shape on the work-piece, making it an extremely versatile laser precision tool. One of the most import features of this product is the embedded video microscope that allows the user to align the target in real-time and also monitor the ablation process. In the example shown below an operator is using the MicroMake system to perform a 100-micron track interruption on a printed circuit board. In this case, the operator used the XYZ stage to align the track under the targeting crosshair and then selected a pre-programmed shape from the software to produce a perfect rectangular interruption.

In the above example, the MicroMake is utilized as a stand-alone micromachining station. It’s user-friendly, air-cooled, plug-and-play table-top set up and operation enable it to be easily integrated as an OEM component in more sophisticated machines and production lines.

At the core of the MicroMake is a sub-nanosecond pulsed Nd:YAG laser offered at either the second or fourth harmonic (532 nm and 266 nm) and a 10x microscope objective. Both wavelengths are available in the standard and “Plus” configuration which offers both enhanced peak power and pulse repetition rate. As a result, the “Plus” configuration is capable of much higher linear processing speeds, though this does come with a slight decrease in spatial resolution. The MicroMake 532 is capable of processing up to 5 mm/s with a 4.5-micron resolution, and the MicroMake Plus 532 can process up to 100mm/s with 5-micron resolution. With the 266 nm version, the maximum peak power is significantly reduced, slowing down the processing time, but by reducing the wavelength by a factor of two, the spatial resolution improves commensurately. Therefore, the MicroMake 266 is capable of processing up to 1 mm/s with a 2.2-micron resolution, and the MicroMake Plus 266 can process up to 40 mm/s with2.5-micron resolution.

出典:https://blog.rpmclasers.com/micromake