Laser Diode business update

- BluGlass has demonstrated working 405nm, 420nm and 450nm laser diode designs

- BluGlass’ 405nm product development is approaching commercial specifications

- Manufacturing supply chain qualification for 2” production is on schedule to complete in the current quarter

- The Company remains on track to deliver sample products this calendar year

- Initial customer revenues anticipated from early CY2021

Australian semiconductor technology developer, BluGlass Limited (ASX:BLG) is pleased to present this update on its laser diode product development. The laser diode business unit has made progress in all three of its development areas:

technology, product development and manufacturing preparedness.

Laser Diode Technology & Product Development

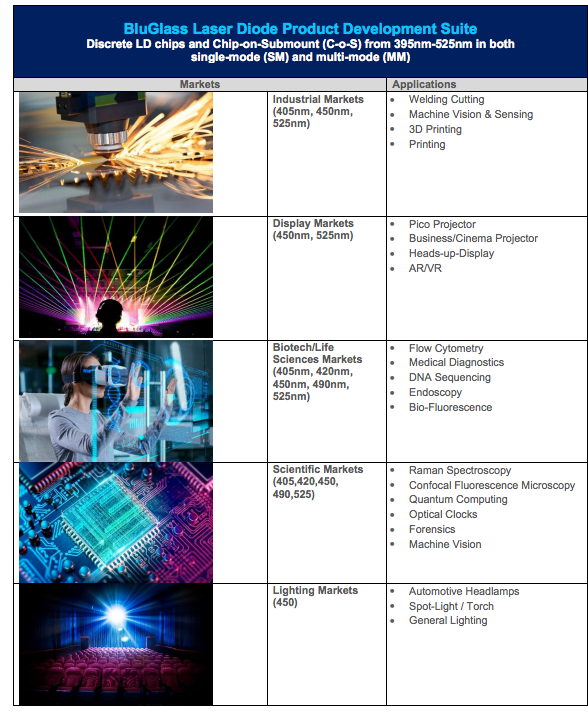

BluGlass is developing a range of laser products to fulfill unmet needs in the gallium nitride (GaN) laser industry. These products include standard laser diode designs and novel, remote plasma chemical vapour deposition (RPCVD) tunnel junction designs, for multiple market segments, including industrial, display and biotech applications.

The company remains on track to deliver initial sample products of one of its standard laser diode designs to customers for testing this calendar year and into early 2021, on the back of promising technical results in three of our laser diode product development roadmaps.

Three different standard laser designs; 405nm, 420nm and 450nm are demonstrating lasing behaviour, following multiple process steps in fabrication into test devices.

Our 405nm design is also showing good performance, approaching commercial specifications in brightness. These results have been verified through multiple fabrication vendors, as we qualify both our laser diode designs and our anufacturing supply chain simultaneously.

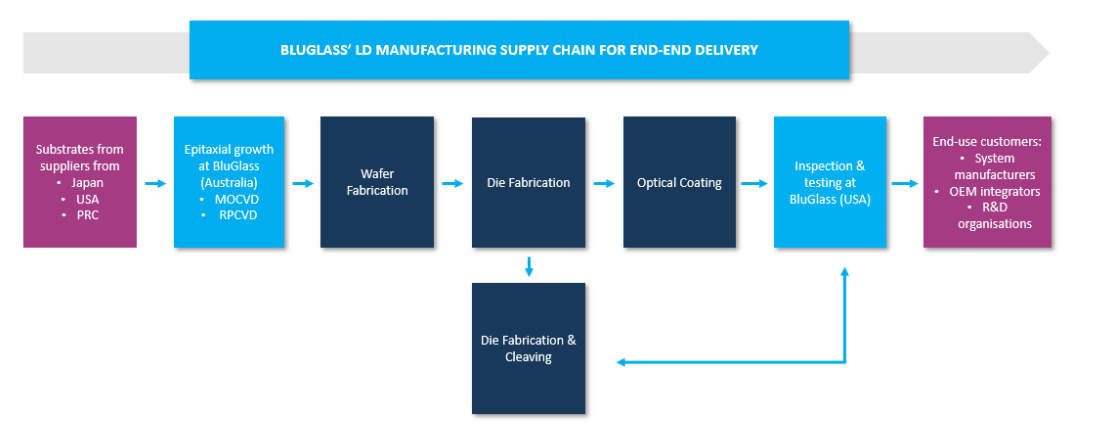

The process to manufacture a laser diode involves many complex steps, supplied by various specialist vendors. These devices are being simulated and modelled, designed, and then grown on wafers at BluGlass’ Australian manufacturing facility. They are then shipped to the US for multiple wafer processing steps including cleaving (being cut into individual laser diode chips) before final optical coating (insertion of coated mirrors to enhance the directional emission/lasing),packaging and burn-in testing (performance reliability testing of 100,000 hours).

There are several customer engagement points that can be initiated at different stages of performance throughout the manufacturing process. Some laser diode customers order custom laser diode wafer development, or R&D devices, before any of the downstream processing steps are required. Other customers require uncoated or unpackaged laser diodes or pre-burn in prototypes for custom applications or preliminary evaluation, with others requiring fully processed and packaged lasers.

Our target customers range from global research institutions requiring custom laser development to OEMs and distributors. BluGlass is establishing collaborative customer relationships to develop customised solutions in several of its target markets.

Manufacturing Preparedness and Supply Chain Qualification

Product development results from wafers grown earlier in the year were initially delayed due to supply chain impacts caused by COVID-19. As a result, we have diversified our supply chain, and are qualifying multiple providers in each segment of the supply chain around the world to help mitigate future delays and ensure that we are working with the best suppliers in each segment.

Processing timelines from design and epitaxial growth through to initial testing has now been significantly expedited. Full supply chain qualification is expected to complete on schedule in the current quarter.

Our US test facility is now fully operational. Our US based team has grown with the addition of two, industry experienced, expert laser diode testing engineers.

BluGlass Laser Diode Product Suite

BluGlass is developing bespoke laser diodes across multiple market segments. Current

product development covers a range of wavelengths from violet (395nm), blue and through to green (525nm) wavelengths for various customer applications including:

BluGlass’ laser diode development, international supply chain qualification and US test facility staffing have all progressed in line with the Company’s published goals towards its commercial manufacturing milestone.

BluGlass now has a number of working laser diode designs, including the 405nm design which is approaching the commercial product specifications for sample customer products.

This announcement has been approved for release by the board.

出典:

https://12da11e8-85f4-ab6f-6419-d0560438e0e3.filesusr.com/ugd/778321_dcaa9ead426542ce92c3f1e3204b3e6f.pdf

この情報へのアクセスはメンバーに限定されています。ログインしてください。メンバー登録は下記リンクをクリックしてください。