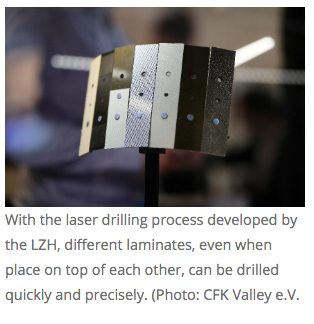

In the LaBoKomp project, the Laser Zentrum Hannover e.V. (LZH) and four partners have developed a laser-based system for drilling rivet holes in composite materials. The LZH was significantly involved in the development of the underlying process and the required system technology. They were able to drastically reduce the drilling time per hole for laser-based processes.

The LZH scientists successfully tested the laser drilling process and the system on so-called “cargo struts”. These are C-shaped struts stabilize the cargo hold floor. With a drilling time of less than 10 seconds per hole, the new method is now on a par with conventional ones – without the disadvantage of tool wear or the risk of delamination.

この情報へのアクセスはメンバーに限定されています。ログインしてください。メンバー登録は下記リンクをクリックしてください。