日本語で読みたい方は、 google chromeで開き、

画面上で右クリックをして、「日本語に翻訳」をクリックしてください

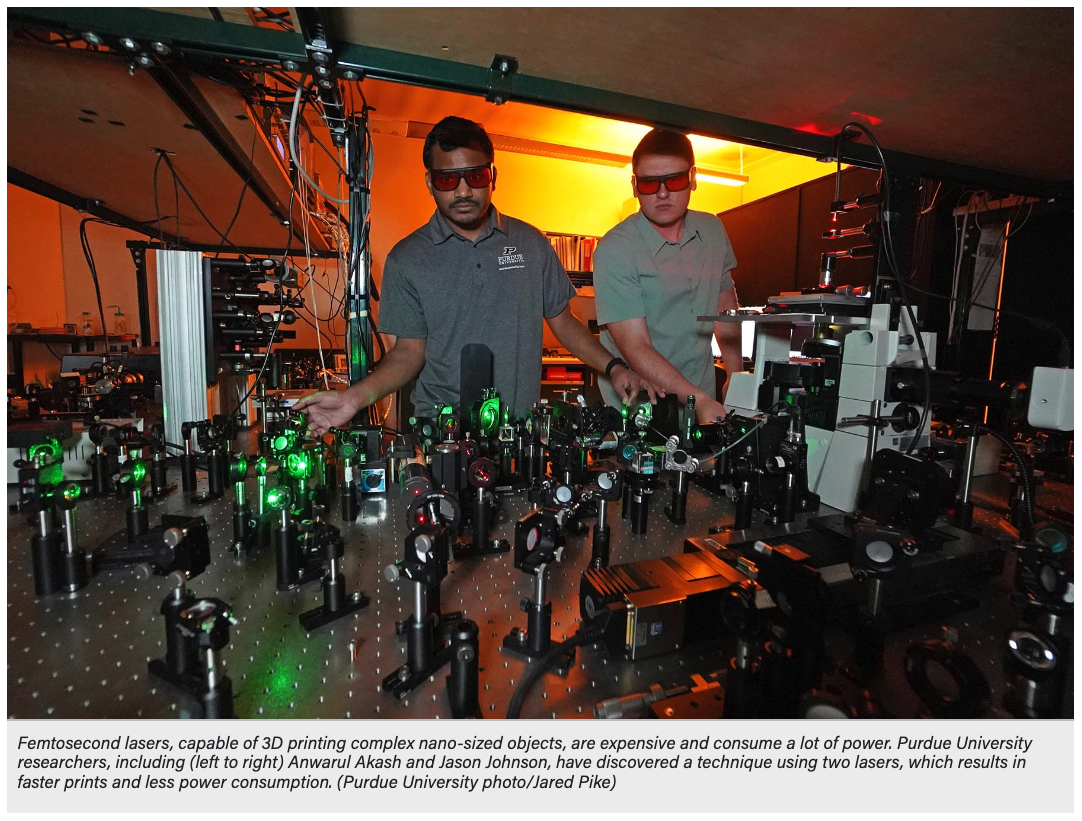

To 3D-print complex high-resolution nanostructures, you usually need very expensive and powerful lasers. Purdue University researchers have developed a new technique that uses two lasers, reducing the cost and power needed, and helping nano-sized 3D printing find wider use in a variety of applications.

Two-photon polymerization is an advanced additive manufacturing technique that traditionally uses femtosecond lasers to polymerize materials in a precise, 3D manner. Although this process works well for making high-resolution microstructures, it isn’t widely used in manufacturing because femtosecond lasers are expensive and increase the cost of printing parts.

“We combined a relatively low-cost laser emitting visible light with a femtosecond laser emitting infrared pulses to reduce the power requirement of the femtosecond laser,” said Xianfan Xu, James J. and Carol L. Shuttleworth Professor of Mechanical Engineering. “In this way, with a given femtosecond laser power, the printing throughput can be increased, leading to a lower cost for printing individual parts.”

この情報へのアクセスはメンバーに限定されています。ログインしてください。メンバー登録は下記リンクをクリックしてください。